WhiteWater’s Statement on SHK Accident Investigation Report at Oceana

Vancouver, BC – We will read and absorb the SHK Accident Investigation report into the tragic Oceana fire and the proposed recommendations. The purpose of this report is to clarify what happened, try to find out why it happened, and how a similar incident can be avoided in the future, a process WhiteWater fully supports. SHK is not investigating the issue of liability, which is being investigated by prosecutors and that investigation is not yet complete, we will therefore make no comment on that.

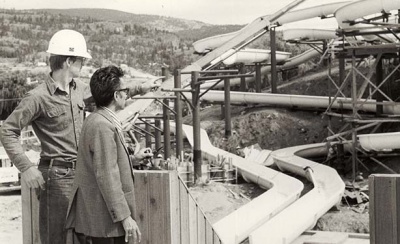

WhiteWater helps build the most iconic water parks in the world, and in our 45 years and thousands of projects delivered we’ve not seen a tragic accident like the Oceana fire occur. Unfortunately, much of the site was destroyed so some things will never be known, because key data was lost. But the draft report found that the most probable cause of the fire was the electrofusion process subcontractors undertook to connect waterpipes under the Rattler slide.

As the report outlines a construction site of this scale runs with multiple specialist contractors on site and WhiteWater would not usually be involved in installation of any piping. However, the plumbing contractor KPT declined to assemble the pipes at heights, instead KPT did the welding of the pipes on the ground to prepare the pre-assemblies, and subcontractors then installed the pre-assembled pipes at height, a process which uses electrofusion exclusively.

The install team had completed the training organized by Liseberg and delivered by KPT as required, were using authorized safety equipment, and applied the electrofusion machine as provided by another of Liseberg’s subcontractors, as automatically preset, reading the QR code on the pipe collars.

As the largest supplier of water and amusement rides in the world, WhiteWater has extensive knowledge with reinforced fiberglass but does not use electrofusion welding and had never come across this type of issue on sites where our products have been installed. WhiteWater was unaware of the fire risks posed by electrofusion, and they were not identified by operational risk assessments onsite the fire risks were generally not known among the contractors on-site or in the industry at large.

“What is crucial is that the construction industry worldwide learn from what has been discovered here and that we share these findings,” said Onno Meeter, President of WhiteWater. WhiteWater now proactively informs our customers and those involved at sites about the risks of hot work in close proximity to our slides, we are communicating this where we can, to protect others from this newly discovered risk.

The focus of this report is about improving safety standards, and WhiteWater is a proponent that industry should reconsider the classification of electrofusion as hot works and adapt standards to clearly reflect this globally. Mr. Meeter concludes, “none of us knew these risks, now we are aware things need to change”.

For media inquiries, please contact WhiteWater CMO, Una de Boer.