Things You Might Not Know About Water Slide Refurbishment

By Ray Sagasky, Team Development Specialist, Construction Supervision

From Asia to the Middle East, and from North America to South America, I have enjoyed traveling worldwide to refurbish water slides over the past few years. Through my work with numerous water park operators, I have encountered some common questions and misconceptions about water slide restoration. I would like to take the opportunity to address some of these queries.

Slide Restoration Lingo: Polishing ≠ Waxing, Resurfacing ≠ Repainting

These terms may seem interchangeable, but they have distinct meanings.

For instance, polishing is done every few months to eliminate minor scratches and restore the slide’s original shine. Waxing, on the other hand, involves applying a protective layer and should be done every couple of weeks.

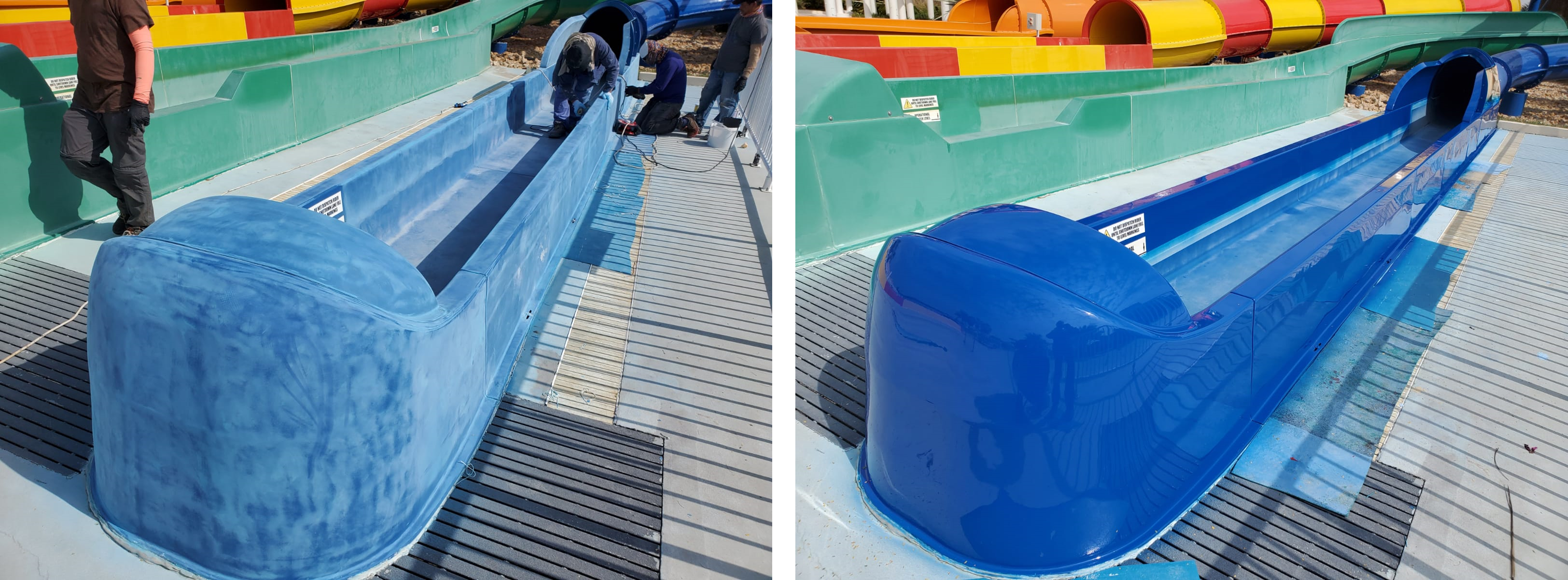

Similarly, resurfacing is often misunderstood. It refers to treating the inside riding surface of the water slide to address significant wear caused by friction over years of use. This process involves reapplying gel coat to the ride surface. It is different from repainting, which is done on the exterior of the slide to address fading due to sun exposure and other environmental factors.

You Don’t Always Need to Resurface

Regarding the interior surfaces of water slides, there are many clients who believe that resurfacing is necessary or were told so without a thorough inspection. However, often sanding and polishing are sufficient.

How can you tell? If there is no fiberglass resin visible, sanding and polishing will suffice. If the surface is extremely worn and faded, resurfacing may be required. It is advisable to consult the original equipment manufacturer (OEM) for an evaluation. They may suggest resurfacing only specific sections of the slide.

Pros and Cons of Resurfacing

Pros: Resurfacing remedies friction wear and extends the life of the slide path by applying a new gel coat. It is also necessary if you wish to change the slide’s colour.

Cons: Resurfacing is more expensive than sanding and polishing. It also results in a textured finish rather than the original glass-like, high-gloss finish, making it harder to clean calcium deposits. Despite this, resurfacing can prolong the life of your investment.

OEM Slide Re-Commissioning May Be Necessary

If the operating parameters change following restoration, the water slide may need to be re-commissioned by the OEM to ensure safe operation. Situations requiring re-commissioning include:

- After resurfacing a water slide

- If the coefficient of friction on the slide path changes due to different coating or coating thickness

- If the ride speed significantly changes after polishing

Can I Glass Over My Seams?

DO NOT glass over water slide seams!

Water slides are composed of large fiberglass sections that move with usage and contract and expand with temperature changes.

WhiteWater’s water slide designs, laminate schedule, material selection, and fiberglass joints with caulking accommodate this dynamic movement. Fiberglassing over the seams could cause the slide parts to crack and potentially result in injuries.

Don’t glass over your water slide seams. Take the time to re-caulk the joints.

Do you have more questions about water slide maintenance and support? Contact our Performance Services team.