The Artistic Engineer Behind FlowRider®: Eliza Dawson

Employee Spotlight—Eliza Dawson

Engineer, FlowRider®, Inc.

Where did you grow up and where did you go to school?

I was born and raised in Tucson, Arizona and got my BA in Studio Art and Spanish from the University of Arizona right out of high school. After having worked in boutique children’s toy stores and in the outdoor industry for a few years, I became fascinated with product design—what differentiates one product from another—and thought I could turn my interests into a career. So I returned to the U of A to get my BS in Mechanical Engineering.

How does your fine arts background influence your job?

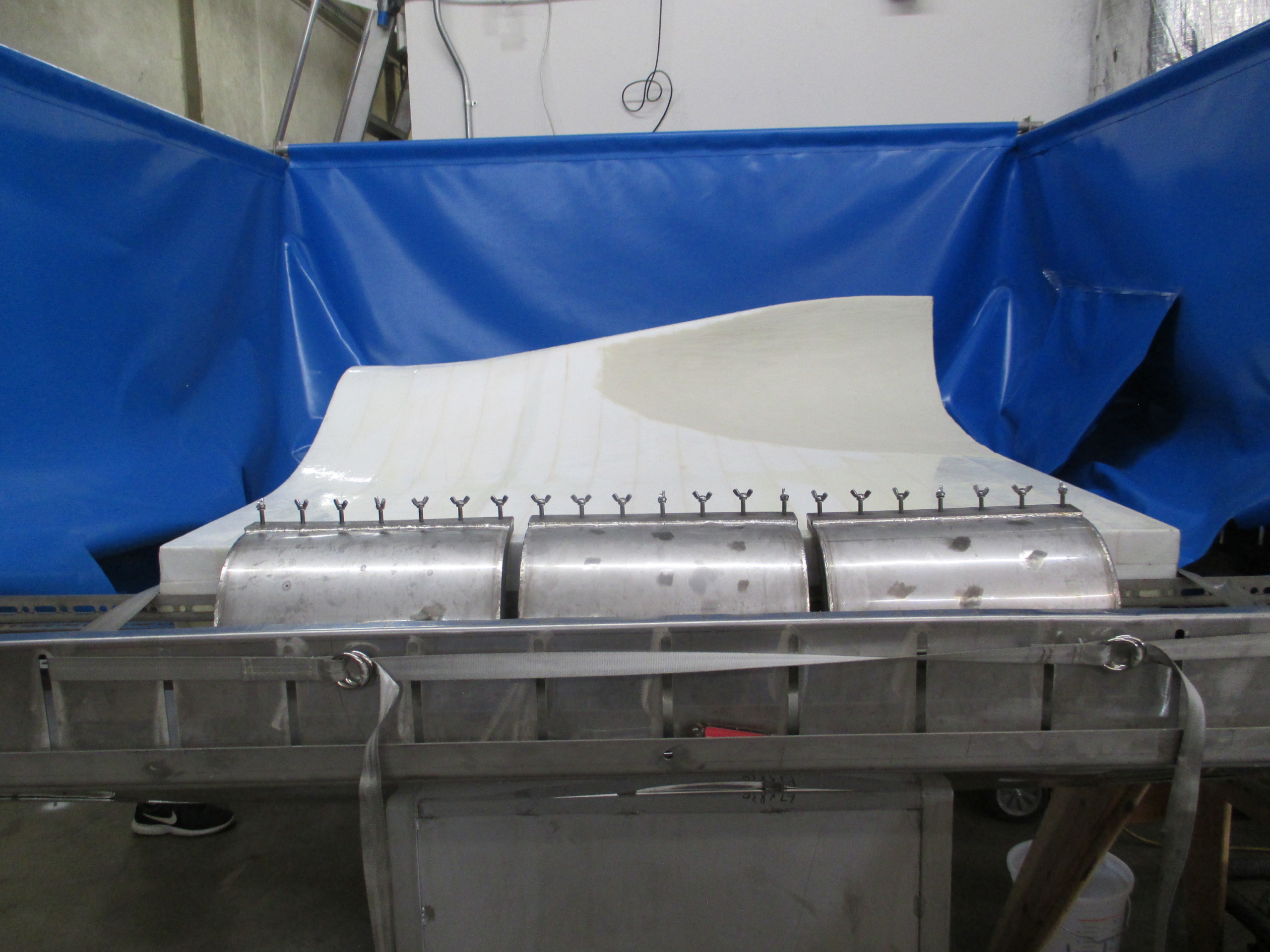

Ever since I was a kid, I have always loved making and building things. In art school, I mostly focused on sculpture and print making because I loved the 3D, tactile nature of those mediums. I wanted to work in a world with more concrete metrics of success and failure and so, decided that engineering was the best path forward. People think that art and engineering are very different, but I use the skills and thinking I developed in art all the time in my job, from designing new products for FlowRider® to building and testing models out in the warehouse.

What is your specialty at FlowRider®️?

We are a cross-functional team at FlowRider®️, so we all wear a lot of different hats. My skills and interests have set me up well to spearhead much of the new product development, with a lot of support and insight from the rest of the team, of course. We are always trying to improve our products and make them more durable, fun, and safe. It’s been an incredible and challenging learning experience getting to see multiple new products all the way through the design process, from concept to final wave! I get to experience the satisfaction of having a great deal of ownership over the entire product development process.

Which products have you seen through the entire development process?

FlowRider TripleTM, FlowRider EdgeTM, FlowCurlTM, and FlowSurfTM. The FlowRider EdgeTM is pretty rad because you can put it in your private backyard with your pool.

What do you like about your job at FlowRider®️?

I really like hands-on work, so my favorite part of my job is when I get to get my hands dirty, either on site or here in the workshop. Our warehouse manager helped me put together a killer space with a large testing tank and tons of tools and materials. We do a lot of concepts testing here, and I’m happiest building and testing scale models out in the shop or gazing lovingly at my hardworking 3D printer.

How are you involved in sustainability?

I’m interested in alternative energy, so I volunteered to be on the WhiteWater Sustainability Committee for Parks and Products—that’s the part of our sustainability initiative that helps clients achieve their environmental goals. We want our products to use less water and less energy, so I work a lot with our pump designer to get the most bang for our buck for volume. For our clients, we know that low operating cost is essential for survival, and sustainability goes hand in hand with efficiency.

What do you do outside of work?

I’ve been rock climbing casually for over 10 years now. I love the movement, problem solving, and the community and friendship I’ve found through climbing.

What is something people are surprised to learn about you?

I do improv comedy, in long form and character-driven scenes. It’s so fun, and I recommend it to anyone who wants to do something that pushes them out of their comfort zone. It’s also a great way to make friends.